brinell and vickers hardness test|brinell to vickers hardness chart : discounter The Vickers hardness test was developed in 1921 by Robert L. Smith and George E. Sandland at Vickers Ltd as an alternative to the Brinell method to measure the hardness of materials. . WEB3 de set. de 2023 · ISADORA VALE - MAIS VIDEOS NO PRIMEIRO COMENTARIO. 193. Sort by: Practical_Truck2076. MOD • 6 mo. ago • Stickied comment. PACK DE VIDEOS 🔥👉 .

{plog:ftitle_list}

Diamond Rush, Gangstar - Suç Şehri, Dragon Ball Z - Martia.

While several variants of hardness testing methods are available to hardness inspectors in the industry today, the Rockwell, Brinell, and Vickers hardness tests remain the .There are three principal standard test methods for expressing the relationship between hardness and the size of the impression, these being Brinell, .Hardness testing is a crucial method in materials science and engineering to evaluate the strength and durability of materials, with Vickers and Brinell being two of the most commonly .The Vickers hardness test was developed in 1921 by Robert L. Smith and George E. Sandland at Vickers Ltd as an alternative to the Brinell method to measure the hardness of materials. .

The three most well known and widely used hardness tests for metals today are Brinell, Rockwell, and Vickers. Here are the basic differences explained. Brinell Hardness Test. The Brinell hardness test is ideal for measuring the hardness of metals with coarse or inhomogeneous grain structures, such as cast iron and softer metals like aluminum alloys. . Vickers Hardness Test. The Vickers hardness test is a versatile and precise method suitable for a wide range of materials, from soft metals to .The Vickers hardness test measures materials with small parts or thin sections. In contrast, the Brinell hardness is used to measure materials with a rough surface, and other methods are unsuitable. The Vickers to Brinell conversion chart can help you convert values between the Vickers and Brinell hardness scales.For both Vickers and Brinell hardness testing, it is common to use reference tables to give the value of hardness for a given indentation size and load, instead of making a calculation each time. 9.11.3 Rockwell hardness test. The third kind of test, mostly favoured in the USA, is the Rockwell hardness test. There are a number of variations of .

The capacity of a material to withstand other harder objects is called hardness. Common hardness test methods include the Brinell test, Vickers test, and Rockwell test. In the Brinell test, usually a hard steel ball with a diameter of 10 mm .The Vickers hardness test is ideal for testing of all metals and is therefore the method with the widest range of application. The hardness test method according to Vickers is described in standards ISO 6507 (Metallic materials – Vickers hardness test – Part 1: Test method) and ASTM E384 (Standard Test Method for Microindentation Hardness (1gf - 200 gf) of Materials .Difference between, Brinell,Rockwell and Vickers Hardness Test What is Hardness? Hardness is the property of a material that enables it to resist plastic Rockwell hardness testing, Brinell hardness testing, and microhardness testing are all methods used to verify heat treatment results. . It’s also critical to specify the correct load for Knoop tests because too-light loads could produce falsely high hardness readings. For Vickers tests, too-light loads create too-small indentations on a .

Brinell Hardness Testing: Involves applying a known load to the surface of the test sample via a hardened steel or carbide ball; Vickers Hardness Testing: Utilises an optical measuring system to measure the area of the impression; Knoop Hardness Testing: Employs a diamond penetrator to impress a sample; Brinell, Vickers and Knoop testers measure hardness based on the size and dimensions of the indentation created by a precisely shaped indenter and the load applied. EMCO-TEST Brinell indentation Indenter Geometry. The Rockwell method uses an indenter with either conical or spherical shape.Steel Hardness Conversion Table. This table shows approximate hardness of steel using Brinell, Rockwell B and C and Vickers scales. These conversion charts are provided for guidance only as each scales uses different methods of measuring hardness. The right hand column show an approximate equivalent tensile strength.

Learn how to use Brinell hardness test units and testing machines to quickly and accurately assess large samples with a coarse or inhomogeneous grain structure – with knowledge and insight from Struers, the world’s leading materialographic and metallographic experts. . An entry-level Vickers, Knoop and Brinell hardness tester, combining .

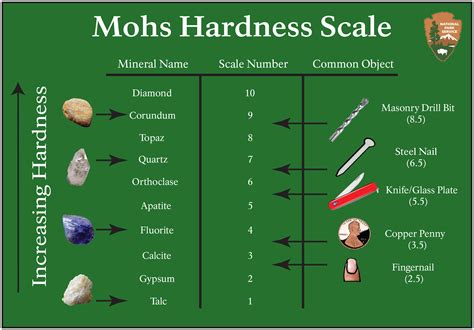

vickers hardness to mohs scale

The Brinell hardness test is named after its inventor, Johan August Brinell. It involves applying a constant load or force to a spherical indenter made of hardened steel or carbide onto the surface of the material being tested. . The Vickers hardness test utilises a diamond pyramid-shaped indenter to create a small impression on the material .For example, you can use the Vickers test, the Brinell test, or the Rockwell test. All three of these tests measure hardness in very different ways. It can be difficult to transfer data between these different tests if you need to compare results from multiple sources or want to report your testing results accurately and concisely in the future. For the Vickers hardness test, a square base pyramid with a opening angle of 136° is used as the indenter (opening angle = angle between two opposite surfaces of the pyramid). The angle was chosen so that the Vickers hardness values are comparable to a certain degree with the Brinell hardness values (applies to approx. 400 HBW or 400 HV). The .

ASTM E384: This standard is for hardness testing on a micro-scale, and therefore includes the Vickers and Knoop hardness tests. ISO 6506: This standard mirrors ASTM E10, as it contains the standard method for .A chart is then used to convert the averaged diameter measurement to a Brinell hardness number. Test forces range from 500 to 3000 kgf. A Brinell hardness result measures the permanent width of indentation produced by a carbide . Brinell Hardness Test. The Brinell hardness test is ideal for measuring the hardness of metals with coarse or inhomogeneous grain structures, such as cast iron and softer metals like aluminum alloys. . Vickers Hardness Test. The Vickers hardness test is a versatile and precise method suitable for a wide range of materials, from soft metals to .In the Rockwell hardness test, a differential-depth method, the residual depth of the indent made by the indenter, is measured.In contrast, the size of the indentation is measured in the Brinell, Vickers and Knoop optical test methods.. The deeper a defined indenter penetrates the surface of a specimen with a specified test load, the softer the material that is being tested.

The easy to use hardness testing software supports the operator with single tests, as well as complex test tasks. Hardness testing according to current standards. Our DuraVision series offers a wide load range from 0.3-250 kg or from 3-3,000 kg for test methods including Vickers, Brinell, Rockwell, Knoop, plastics testing and carbon testing. The Brinell, Vickers, Meyer, Rockwell, Shore, IHRD, Knoop, Buchholz, and nanoindentation methods used to measure the indentation hardness of materials at different scales are compared, and main issues and misconceptions in the understanding of these methods are comprehensively reviewed and discussed. Basic equations and parameters . Direct Calibration. In direct calibration of the three conventional hardness machines (Brinell, Vickers, and Rockwell), the main influencing parameters of the hardness testing machines shall be calibrated (ISO 6508-1 2016; ISO 6506-1 2014; ISO 6507-1 2018; ASTM 2017a, b, c); these influencing parameters are as follows:. Force calibration. The Vickers Hardness test (ISO 6507) is used to characterize hardness of various solid materials (metals, ceramics, etc.). A diamond pyramid is pressed against the solid with a certain normal load and the hardness is calculated based on the imprint left on the surface. . Brinell Hardness numbers in parentheses are outsite the range (HB>630 .

With the Brinell hardness test, a carbide ball is pressed into the material. The indentation surface serves as a measure of the hardness. Vickers hardness te.The Brinell hardness is designated by the most commonly used test standards (ASTM E10-14 [2] and ISO 6506–1:2005) as HBW (H from hardness, B from brinell and W from the material of the indenter, tungsten (wolfram) carbide). In former standards HB or HBS were used to refer to measurements made with steel indenters.The Brinell, Vickers & Rockwell tests–Brinell test indenter is made of hardened steel. Vickers test indenter is made of diamond. Find out more at UNSW. . The Rockwell test is designed as a method of hardness testing for rapid comparative analysis. The depth of the impressions are measured and are rated on a dial calibrated, inversely, into .

rockwell hardness scale comparison chart

The Brinell hardness testing method consists in applying a certain force over a carbide tungsten ball indenter, then reading the diameter of the impression, in order to obtain the final result. . The Vickers hardness testing method consists of applying a certain force over a diamond pyramid 136° indenter and then reading the indentation . The three most widely used today are Brinell, Rockwell, and Vickers. Brinell Hardness Test. Proposed by J.A. Brinell in 1900, the Brinell Hardness Test was the first standardized hardness test to be used, and it is still widely used today. In this test, the metal surface is indented with a 1 to 10 mm diameter steel, or most recently, a tungsten .

rockwell hardness comparison chart

difference between vickers and rockwell

Conference Championship day. I put a discount on my OnlyFans, we have football prize giveaways for the games, and Simona and I are doing a Live Cam after the game.

brinell and vickers hardness test|brinell to vickers hardness chart